ANIMAL BIOCLIMATOLOGY

BIRDS

- The domestic animal, like all living beings, lives in an environment constituted by the set of natural and artificial or prepared external conditions, which exerts its performance on it.

- Ecological aptitude is conditioned by two basic factors: climatic and edaphic.

- Direct influence, through the air temperature, and the solar radiation, and to a lesser degree the humidity, by its close relation with the atmospheric heat.

- Climatic components condition the organic functions involved in maintaining normal body temperature.

- Indirect influence, through the quality and quantity of vegetables indispensable for animal husbandry, and whether or not it favors infectious-contagious and parasitic diseases.

- In short, the great importance of the environment for the exploitation of domestic animals is due only to its influence on the phenotype, that is, on the exteriorization of the inheritance, on the genotype of the individuals; Allowing its full exteriorization or limiting it.

- The largest concentration of poultry farmers in Brazil is located in the Southeast and South regions of the country, notably in the latter region, where in the fall and spring temperatures reach 20ºC in a single day. In these regions the thermometers reach between 33 and 44ºC in the summer.

- The death of birds due to thermal stress represents a significant loss for producers.

- In addition, excessive heat causes problems of low feed conversion, weight loss, reduced egg laying and egg quality.

- With recent advances in genetics, nutrition and sanitation, enormous increases in poultry productivity have been achieved.

- To such an extent that poultry products – meat and eggs – are now among the cheapest sources of animal protein, only supplanted by cow’s milk.

- Together with these advances, it is necessary for poultry to reach high levels of productivity a strict sanitary control and the application of technology in the design of facilities that will mitigate the effect of temperature on birds.

INSTALLATIONS

- Problems with heat can be softened from the choice of location for the construction of the aviary.

- The breeder should take advantage of the available plateaus on his property and privilege the northern façade. The north side, more sunny, should be shaded with trees and the south side kept unobstructed.

- The northern side is always hit by the sun, which in summer can have its effects brightened, but it ensures greater illumination and less humidity in the winter, especially for the southern region of the country.

- Even if the farmer is forced to divert the axis of the aviary, however, the care is still under construction. The right foot that today varies between 2.20 to 2.50 meters in most aviaries, is expected to rise to 3 meters, according to the literature.

With the right foot higher, even with less wind the same air renewal can be achieved.

- With the right foot higher, even with less wind the same air renewal can be achieved.

- A larger eave is also required, with an angle of 60⁰ between the height of the wall, which is close to the ground, and the projection of the eave. The higher the wall, the greater the need to be the eave to protect from the sun or better, the greater the roof trim.

- With this small modification, it is avoided that between sun in the henhouse. And it should not be forgotten the installation of a lining between the roof and the area where the birds are

- Another important precaution is the choice of roofing material.

- French tiles have the advantage of offering greater delay in the transmission of heat waves, but they require perfect fit and are more difficult to handle in the event of need for corrections.

- Since asbestos is a light material and facilitates repairs, however regardless of the type of tile chosen, it is advisable to paint them in white and always keep them clean.

- A glossy coating of high durability reduces the absorption of heat.

- Studies show that a dark, dirty roof represents 80% absorption of the heat collected while it is clean, this absorption is only between 20 and 40%. Like the roof, internal cleaning requires regularity.

- The beds, which receive the poultry waste, function as a thermal insulation in the summer.

- By keeping them clean, the warming of the gases released by manure is avoided.

- For the aviary to have good ventilation, it is necessary a larger area of lantern, the superimposed roof of the ridge, whose function is just to air environments.

- With more lantern area, the wind crosses the aviary, which, associated with the placement of tubes on the roof for its exit, produces very positive effects in the renovation of the air in the environment

- In the cold season, notably in the southern region, all facilities have pipes, and these pipes serve to promote hygiene ventilation, removing carbon dioxide and ammonia produced by the breathing of animals, waste and combustion of heaters, firewood or To liquefied petroleum gas.

Size of the space to be covered and the average temperature of the region.

- Size of the space to be covered and the average temperature of the region.

- Another good practice is shading; Combined with the implantation of lawns around the aviary.

- The lawn absorbs solar radiation and produces moisture, which ultimately reduces the temperature around the shed.

- Even with these practices that attenuate the ambient temperature for birds, especially in the summer, it is fundamental to reduce the density of chickens in the aviary.

- The current measure is 17 to 18 birds per square meter, but the “ideal” seems to be 10 to 13 birds per square meter.

NUTRITION PROGRAM FOR BIRDS IN HOT CLIMATES

- The birds show the maximum of their performance if placed in temperatures inside the zone of thermal comfort that, if adults, is between 14 and 25ºC.

- In the conditions of caloric stress the birds undergo physiological alterations like breathing breath, and consequently, respiratory alkalosis.

- Apparently, the main problem of high temperature is the reduction in feed consumption.

- By raising the temperature inside the aviaries, the temperature required to maintain body temperature is reduced and the birds consume less feed.

- However, the relationship between body heat production and internal temperature of the aviaries is not linear, since the energy requirements of the birds are increased to initiate heat loss by respiratory evaporation.

- Several factors influence the performance of birds subjected to heat stress, with nutrition being one of them. The energy requirement is one of the nutritional aspects that is most influenced by the ambient temperature.

- By raising the ambient temperature, it reduces energy consumption.

- However, above 27-28 ° C, the decline is greater since the bird is subjected to heat stress and to factors such as wheezing and other factors, which interfere with the available time of feed consumption.

- Approaching 28 ° C, the energy available for production is dramatically reduced and around 33 ° C becomes negative.

- Thus egg production declines, unless another energy source is used, such as body energy (muscle and adipose tissue) reserves. The bird goes into severe negative balance at 33⁰C.

- The use of pelleted rations results in better weight gain and food consumption than the meal, a phenomenon justified by the increase in feed density through pelleting.

- The use of fats in feed is an alternative to be used in periods of heat stress.

- This is because the fats increase the palatability of the rations and provide a smaller increase of heat, compared to proteins and carbohydrates.

- In this particular, the use of saturated fat is more convenient than unsaturated due to oxidation which can be accelerated by heat. Feed consumption can be stimulated under hot stress conditions.

- In the case of laying hens, performance during the rearing period influences the economic return during the production period.

- In case of heat stress, the bird can turn to depend on its own reserves to maintain production.

- In general, the higher the body weight at sexual maturity, the greater the body weight during the posture and, therefore, the greater the reserve energy potential and the higher the feed intake.

- It should be noted that an extremely obese bird is undesirable, but layers with optimal ideal weight, with reasonable body reserves, will be able to better cope with heat stress situations, producing a greater number and mass of eggs.

COOLING SYSTEMS FOR THE THERMAL CONTROL OF POULTRY GROUNDS

- Among the environmental factors, the thermal factors, represented by thermal radiation, temperature, humidity and air movement, are those that affect the bird more directly, as they compromise maintenance of homeothermia.

- Thus an environment is considered comfortable for the bird when the heat resulting from its metabolism is lost to the environment without detriment to its yield.

- Occurring in general, from the second week of life in environments with temperatures of 15-18⁰C to 22-25⁰C and relative humidity of 50% to 70%, values that are difficult to obtain in Brazilian poultry plants

- Thus, when the problem of caloric stress has been detected, it has been tried to alleviate this situation with the use of artificial thermal conditioning technologies, which, in most cases, are incompatible with the regional climatic reality or technically unsuitable

- Initially, it is essential that the installation contemplate, to the maximum, all the resources of the natural thermal conditioning, and only if thermal comfort has not been reached, one must use the appropriate artificial packaging, involving ventilation systems, heating And cooling.

Natural Thermal Conditioning

- Considering that Brazil is located to the south of the line of the Equator, predominantly until the latitude 30º South, soon in the hottest band of the terrestrial terrestrial, one must attend the following points in the implantation of the project:

- Location

- Guidance

- Arrangement of buildings

- Protection against sunshine: roofing

The protection against direct sunlight is achieved through the roof, and the most usual roofs can consist of the following materials, in the sequence of their thermal quality, from best to worst:

- The protection against direct sunlight is achieved through the roof, and the most usual roofs can consist of the following materials, in the sequence of their thermal quality, from best to worst:

⇒ styrofoam between two aluminum blades

⇒ thatch

⇒ madeirit: plywood, 6mm thick, corrugated, top coated by aluminum blade.

⇒ mud

⇒ Aluminum

⇒ Asbestos

⇒ Galvanized sheet or galvanized iron

- You can also use some devices to improve coverage:

A) Use of linings under cover

B) Paints with light and dark colors

C) Use of insulating materials

D) Materials of high thermal inertia

E) Use of water spray on the roof

How still:

A) Width of the shed and height of the roof

B) Beirais

C) Lanternins

D) influence of the neighborhood on the

(E) Surrounding landscaping – vegetation – windbreaks

F) Natural ventilation

Systems of Artificial Thermal Conditioning in Installations

Forced ventilation

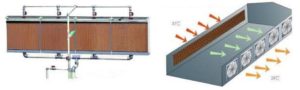

- Forced ventilation is adopted whenever the natural media does not provide the necessary air renewal index and / or lowering temperature, with the advantage of being independent of atmospheric conditions and allowing the treatment of air (filtration, humidification, drying, etc.). .), And its better distribution.

- The fans used in poultry houses should be arranged with the flow in the width direction of the shed, in ways to suck fresh air from the outside by injecting it inwards and expelling the stale air from the back side.

- The fans should be positioned in the prevailing wind direction so that they do not have their efficiency reduced.

- As in Brazil, most of the prevailing winds come from the south, and as the sheds should be oriented east-west, the fan direction is normally perpendicular to the length of the shed.

- The fans should be at the height corresponding to half of the right foot of the building, where the air is cooler, with the jet directed slightly downwards, without however directly affecting the head of the birds; Thereby obtaining the removal of hot and moist air near the zone of occupation of the birds.

- The number of fans to be used in a matrix shed depends on the flow rate, the shed volume, the time of year and the age of the birds.

- It is advised that each bird at each age has a guaranteed minimum air renewal rate and is disturbed with a maximum air velocity as shown in the tables.

- The main objectives of ventilation are:

⇒ Eliminate excess carbon dioxide from the metabolism of birds.

⇒ Prevent accumulation of ammoniacal vapors (ammonia) from manure.

⇒ Eliminate excess moisture from pulmonary evaporation, faeces and drinking fountains.

⇒ Reduce excessive heat.

- Factors that favor the production of ammonia inside the shed.

⇒ Poor ventilation.

⇒ High humidity in bed.

⇒ High population density.

⇒ Quantity and quality of bed.

⇒ High temperatures.

- Consequences observed in birds due to the excess of ammonia inside the shed:

⇒ Decreased food consumption.

⇒ Reduction of respiratory rate.

⇒ Injury to the respiratory tract.

⇒ Conjunctivitis.

⇒ Break in production.

⇒ Greater pre-arrangement of birds to infections.

Air Temperature Cooling

- A relevant aspect is that in some cases, in extremely hot regions, simple, natural or artificial ventilation may be insufficient to promote temperature cooling.

- This is because simple ventilation does not make it possible to reduce the temperature of the air to be incorporated into the environment and, therefore, the minimum temperature that will be obtained inside the shed will be exactly that of the external air used in the ventilation, which often assumes Values far above desirable.

- In this case, it is necessary to promote pre-cooling of the air entering the premises.

- One of the most effective forms of air cooling is the evaporative adiabatic cooling, which allows reduction of up to 12⁰C in the driest regions and an average of 6⁰C under Brazilian conditions.

- The adiabatic (evaporative) cooling system can be obtained by several processes, especially:

A) Cooling of internal air through nebulization associated with ventilation.

B) Water spraying, frontally the fan or directly on the bird.

C) System of porous material coupled to fan and air distribution tube.

- In short, the environment and the birds are the main determinant of the possibilities to obtain even greater benefits with the application of the technologies conquered.

- In this regard, poultry farmers and technicians should pay attention to the fundamental importance of redoubling the attention that was usually given to the planning and design phase of poultry projects.

- So that these are compatible with the climatic reality of each region, allowing the birds comfort conditions and, consequently, maximum productivity, in such a way that the cost-benefit ratio is, more and more, close to the ideal.