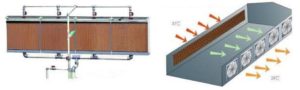

In the field of animal production, a significant progress of the poultry industry, as commercial cutting chicken is, today, one of the animals with greater performance efficiency and speed of development. One of the biggest problems in commercial broilers are the high environmental temperatures found inside the premises, arising from architectural features and materials used in the construction of the facilities, which are associated with physical and physiological characteristics of birds, limited to maximum productivity provided by the genetics of the animals. The use of rainwater that would be wasted, through storage and sprinkling of the same on the cover is an interesting alternative for the sustainable development of the poultry sector, since it promotes the thermal cooling facilities, which may help to achieve better results on the productive performance of animals. In view of the above objective with this work to evaluate a conventional sprinkler system on the cover and designing a sustainable system of cooling of thermal environment by applying water on the galvanized steel covering, in commercial facilities for broilers, in the Central-West region of Brazil. The evaluation considered the following variables: indices of thermal comfort, radiant heat load (CTR), tile surface temperature, temperature of the surface of the bed, working time and energy consumption for cooling systems heat poultry houses with and without spraying on the cover, water consumption for sprinkler system and performance indices. The survey was conducted in six industrial production of avian broilers system integration of Perdigão Agroindustrial S/A, in the region of Rio Verde, Goiás, during the final phase of creation (21 to 42 days of age), from January 2007. The six aviaries were equipped with similar negative ventilation system and internal fogging, and in three of these installed additional cooling system with sprinkling water on the cover. It was used a completely randomized design (DIC) with two treatments and three repetitions. The statistical analysis of the performance data of the birds was performed in SAS ® software (STATISTICAL ANALYSIS SYSTEM). The thermal environment was evaluated on the basis of the days of lesser and greater maximum external air temperature in the initial phase (21 to 31 days of life of birds) and the final stage (32 to 42 days of life of birds) for the use of spraying on the cover. To choose the characteristic days were held daily analysis all the climate data of the external and internal environment of the facility. The drive time from sprinkler system as well as the ventilation system and internal fogging the aviaries, took place on the basis of internal temperature of poultry houses for each treatment. The potential use of spraying on the cover using rainwater was considered according to climatological normals of the Ministry of agriculture and agrarian reform is available on the National Institute of meteorology (1961 to 1991). The sprinkling water on the coverage provided the following results: a) reduction of up to 27° c in the temperature of the surface of the tile; b) 0.25 m temperature Reduction below the roof by up to 10° c for both days characteristic of lower and higher maximum external air temperature; c) temperature Reduction to the level of the birds up to 3° c in the day of highest maximum temperature of external air in the initial phase of use of the spraying on the cover; d) increase of up to 6% in relative humidity at the level of the birds in the day lower maximum temperature characteristic of external air in the final stages of use of the spraying on the cover; e) maintenance ITGU range between 77 and 86, respectively for the days of smaller and larger maximum temperature of external air, both at the initial stage as end of use of spraying on the cover; f) maintenance of CTR less than 500 W m-2 for both days characteristic both in the initial stage as end of use of spraying on the cover; g) reduction in operating time of the second group of Hood of 4.8%, in the third group of 7.5% and misting pump 9.6%; h) water consumption of approximately of 5,865 l. h-1. I) reduction in the mortality rate of 2.03%; j) improvement in feed conversion of 6.09%; k) increase in average body mass gain to 0.109 kg slaughter animal-1; l) 48.3 increase in Productive efficiency index; m) in the temperature of the surface of the bed there was no significant difference between treatments.

In the animal production field it is really visible and significant the poultry industry progress, where the broiler chicken is one of the animals with the best efficiency in its development speed. One of the worse problems in the accommodation of these broiler chickens is the high environmental temperature inside of these facilities, caused by the architectural characteristics and the material used to build these accommodations. These problems associated with the physical and physiological characteristics of birds limit the highest productivity provided by the genetic of these animals. Using the pluvial water, which would be wasted, through the store and aspersion of this water on the covering, it is one interesting alternative to the sustainable development of the poultry sector, once it promotes the thermal cooling of the facilities, contributing to reach better results in the productive development of these animals. In this way, the objective of the present work is to evaluate one conventional cooling system upon the covering and project a sustainable thermal cooling system using the water on the zinc steel covering in some commercial broiler production housing in the Brazilian centro-oeste . Some variables were considered during the evaluation, such as: thermal comfort index; thermal charge radiating (TCR); roof surface temperature; bed surface temperature; operation duration and power consumption of the thermal cooling systems of the facilities, with and without the aspersion on the covering; water consumption through the aspersion system, animal performance index. The research was made in six commercial farms integrated of the Perdigão Company, in the region of Rio Verde, Goiás, during the final breeding phase (21 to 42 days) in the period of January of 2007. The six facilities were equipped with the same negative tunnel ventilation and fogging system, but in three of them was settled an additional cooling system with water aspersion on the covering. We used a completely randomized design with two treatments and three repetitions.The statistical analysis of the data of the animal performance was made using the software SAS® (STATISTICAL ANALYSIS SYSTEM). The thermal environment was evaluated using the data of the characteristic days with the lower and higher temperatures of the external air in the beginning phase (21 to 31 days of life) and in the final phase (32 to 42 days), using the aspersion on the covering. To search the characteristic days were made daily analysis of the climatic data of the internal and external environment of the facilities. The duration of the aspersion system working, as well as the ventilation and fogging system of the aviaries, were searched using the internal temperature data of the aviaries for each treatment. The potential use of the aspersion on the covering using the pluvial water was considered according to the climatological rules of the Agricultural Ministry available in the National Meteorological Institute (1961 to 1991). The water aspersion on the covering provided the following results: a) reduction of until 27°C in the roof surface temperature; b) temperature reduction to 0.25 m under the roof for until 10°C for both characteristic days with the lower and higher temperatures of the external air; c) temperature reduction in the level of the birds until 3°C in the characteristic day with the higher temperature of the external air in the beginning phase using the aspersion on the covering, d) increase of until 6% in the relative humidity in the level of the birds in the characteristic day of the lower temperature of the external air in the final phase using the aspersion on the covering; e) maintenance BGHT between 77 and 86, respectively to the characteristic days of lower and higher temperature of the external air , both in the beginning and final phases using the aspersion on the covering; f) TCR maintenance inferior to 500 W.m-2 for both characteristic days as much as in the beginning and final phases using the aspersion on the covering; g) time working reduction of the second extractor group of 4.8%, in the third group of 7.5% and 9.6% in the fogging system; h) approximated water consumption of 5,865 L.h-1; i) 2.03 % of mortality reduction; j) 6.09 % increase of the feed conversion; k) increase of 0.109 kg.animal-1 of the body weight during the slaughter; l) increase of 48.3 in the productive efficiency index; m) it doesn t have any significant difference among the treatments in the bed surface temperature.